A glass lathe machine is a type of lathe that is specifically intended for cutting and shaping glass elements with extreme precision. Unlike traditional metal or wood lathes, a glass lathe machine works at regulated speeds and features special holding mechanisms to protect delicate glass components.

Product

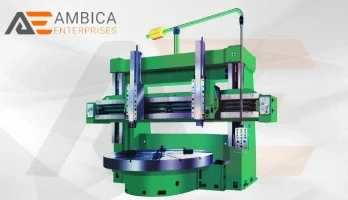

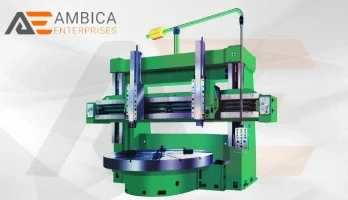

Vertical Turning Lathe Machine

Turning Diameter

800-4,000 mm

Table Diameter

630-3,500 mm

Product

Capstan Lathe Machine

Turret Head

Holds 4-6 tools

Spindle Speed Range

40-2000 RPM

Product

Hollow Spindle Lathe Machine

Grade

Semi-Automatic

Machine Layout

Horizontal Lathe

Product

Tool Room Lathe Machine

Lathe Machine

Manual

Length of Bed

4.5/5/5.5/6 Feet

Product

Belt Drive Lathe Machine

Material

Steel Sheet

Grade

Semi-automatic

Product

Turret Lathe Machine

Layout

Horizontal, Vertical

Material

Cast Iron and Steel

Product

Speed Lathe Machine

Material

Cast Iron or Steel

Spindle Speed

1000-4000 RPM

Applications of Gap Bed Lathe Machines

Gap bed lathe machines are specialized tools designed with a removable section in the bed, allowing for the machining of larger workpieces that wouldn’t fit in a standard lathe.

Applications of Automatic Lathe Machines

Automatic lathe machines are designed for high-speed, high-precision machining with minimal manual intervention. These machines can operate continuously, making them ideal for mass production. Here are some key applications of automatic lathe machines across various

Applications of Belt Drive Lathe Machines

Belt drive lathe machines are widely used in various industries due to their reliability, versatility, and ease of maintenance. These machines utilize a belt-driven mechanism to transfer power from the motor to the spindle, allowing for smooth operation and variable speed control. Here are some key

Applications of Wood Lathe Machines

Wood lathe machines are specialized tools designed for shaping and machining wood into various forms. They are widely used in woodworking and craft industries due to their versatility and precision. Here are some key applications of wood lathe machines