Understanding the Different Types of Lathe Machine

Lathes are fundamental machines in the manufacturing & machining industry, permitting the precise shaping of materials like metal, wood, and plastic. With different types of lathe machine available, each scheduled for specific applications, it’s easy to understand which one suits your needs best. In this blog post, we’ll explore the most standard types of lathe machines and their unique features.

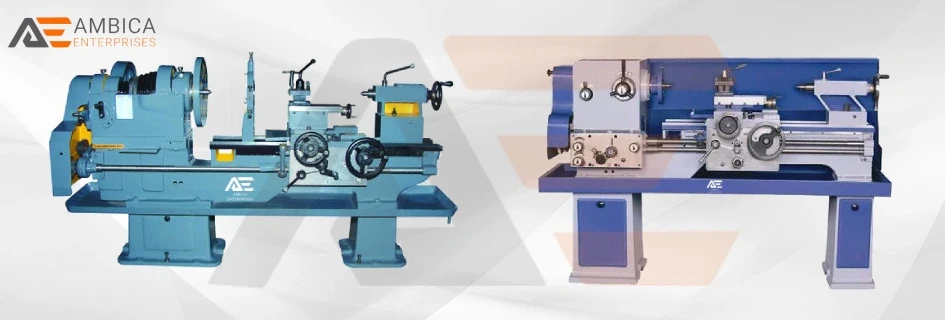

Engine Lathe Machine

The engine lathe machine is one of the numerous widely utilized and recognizable lathes in machine shops due to its versatility. It works by holding and rotating a job piece on a spindle while a stationary cutting tool shapes it. This straightforward setup allows the engine lathe to perform a wide range of tasks, including turning, facing, threading, and drilling, assembling it suitable for both heavy-duty or light-duty projects. Engine lathes arrive in assorted sizes, from smaller bench models to large industrial kinds, and are typically classified by their bed length and speed range.

Engine Lathe Machine Features

- Adjustable speed settings

- Manual or automatic feed

- Tailstock for supporting long workpieces

Applications: Engine lathes are utilized for turning, drilling, threading, & facing operations, making them superior for assorted metalworking tasks.

Turret Lathe Machine

Turret lathes are specifically designed for producing large quantities of identical parts efficiently. They feature a rotating turret head that holds several cutting tools at once, allowing quick changes between operations without manually swapping tools. This setup significantly reduces downtime, as the turret can be indexed to bring each tool into position as needed for different machining steps.

Turret lathes excel in repetitive presentation tasks, assembling them ideal for manufacturing large batches of identical parts. They are commonly used for operations such as boring, reaming, and drilling, permitting for efficient, complex jobs without the demand for constant tool changes. This versatility and efficiency make turret lathes valuable in mass-production settings where high volume and consistency are essential.

Turret Lathe Machine Features

- Multiple tool stations for quick tool changes

- Automatic or semi-automatic operation

- High precision and efficiency

Applications: Commonly utilized in the production of screws, bolts, & other small parts, turret lathes excel in batch manufacturing.

CNC Lathe Machine

Computer Numerical Control (CNC) lathes are advanced, automated machines used to perform detailed and precise machining tasks. Unlike traditional manual lathes, CNC lathes rely on programmed computer instructions to control cutting actions, making them capable of executing complex shapes and intricate details with high accuracy. These machines allow operators to set various parameters, like spindle speed and tool movement, to ensure consistent and repeatable results, which is essential for high-quality production.

CNC lathes are especially valuable for industries needing precise and intricate parts, like aerospace, medical equipment, and electronics manufacturing. Their automation streamlines production, making them excellent for large batch production while maintaining exacting standards for accuracy and detail.

For more info about the sand blasting nozzle visit our website.

CNC Lathe Machine Features

- Computerized control for precise movements

- Ability to produce complex geometries

- Reduced operator intervention

Applications: CNC lathes are widely utilized in industries requiring high accuracy, alike aerospace, automotive, and medical equipment manufacturing.

Toolroom Lathe Machine

Toolroom lathes are highly precise machines used primarily to manufacture tools, dies, & prototype parts that require fine detail. Smaller and more accuracy-focused than typical engine lathes, toolroom lathes deliver refined control over speed & feed rates. This precision creates them perfect for creating complex parts, intricate tools, & custom prototypes. They are widely utilized in workshops and research labs where tight tolerances & custom specifications are essential. With their focus on accuracy, toolroom lathes are perfect for tasks where meticulous attention to detail is critical.

Toolroom Lathe Machine Features

- Fine adjustment capabilities

- High-quality construction constantly

- Contains a wide range of accessories

Applications: Standard for tool and die makers, these lathes are utilized for intricate work that demands tight tolerances.

Mini Lathe Machine

Mini lathe machines are small, portable machines scheduled for hobbyists & small workshop use. These lightweight, easy-to-use lathes are excellent for DIY projects, beginners, or small-scale tasks. Superior for working on small items like pens, rings, & small metal parts, mini lathes could handle essential operations like turning, facing, & drilling. Despite their compact size, they offer many functions similar to larger lathes, assembling them versatile tools for personal projects and light production work.

Mini Lathe Machine Features

- Small footprint

- Suitable for lighter materials

- Affordable pricing

Applications: Mini lathes are great for small projects, model making, & educational purposes, providing an accessible way to learn machining skills.

Wood Lathe Machine

Overview: Wood lathes are machines scheduled especially for shaping, carving, & finishing wood projects. Unlike metal lathes, which handle harder materials, wood lathes operate at more elevated speeds to suit wood’s softer texture. Commonly utilized in woodworking, they’re excellent for crafting items like furniture legs, bowls, & decorative pieces. Wood lathes come with specialized tools for tasks like shaping, grooving, & carving, creating them essential for creating smooth, detailed finishes on wood-based projects.

Wood Lathe Machine Features

- Adjustable speed settings suitable for wood

- Often includes a tailstock and tool rest

- Specialized tools for wood turning

Applications: Utilized in furniture making, crafts, & artistic woodwork, wood lathes permit creative designs & detailed finishing.

We provide different types of lathe machines such as engine lathe machines, turret lathe machines, CNC lathe machines, bench top lathe machines, toolroom lathe machines, hollow spindle lathe machines, wood lathe machines, metal lathe machines, and also offer abrasive blasting machine, sand blasting machine, portable sand blasting machines, grit blasting machine, sand blasting spare parts, shot blasting machine, granite engraving machine, etc.