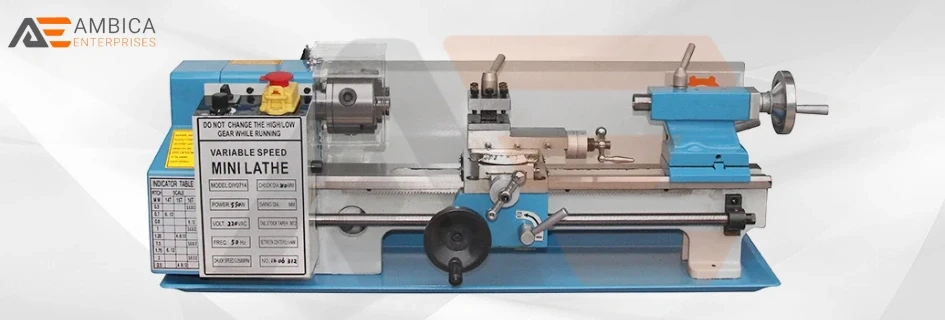

What is a Mini Metal Lathe?

A mini metal lathe machine is a small, versatile machine utilized to shape metal and different materials. Unlike larger lathes, mini lathe machine is scheduled for smaller workpieces and are amazing for precision tasks like turning, drilling, and threading. They are normally utilized in small workshops, by hobbyists, & for prototyping.

The Mini Metal Lathe Machine is ideal for those who need a practical, space-saving solution without compromising on performance. These machines are designed to fit into smaller workshops, garages, or classrooms and are affordable, making them perfect for hobbyists and beginners who want to explore metalworking.

For more info about the sand blasting machine visit our website.

Features of Mini Metal Lathe Machine

- Compact Size: Mini lathes are created to fit in narrow spaces, creating them excellent for home workshops or small machine shops.

- Variable Speed Control: Most mini lathes offer adjustable speed settings, permitting you to tailor the rotation speed to suit different materials and tasks.

- Precision: Equipped with fine adjustment features, mini lathes enable detailed work, ensuring high accuracy & a smooth finish.

- Ease of Use: accompanied by straightforward controls and an easily operated design, mini lathes are accessible for beginners while still providing functionality for experienced machinists.

- Affordability: Generally more reasonable than larger industrial lathes, mini metal lathes offer superior value for hobbyists & small businesses.

Benefits of Using a Mini Metal Lathe

- Versatility: Mini lathes could be utilized to assemble a broad scope of projects, from small machine parts to artistic pieces. Their versatility creates them proper for assorted materials, including metals, plastics, & wood.

- Space-Saving: Ideal for those with limited space, mini lathes could easily be stored away when not in use, keeping your workshop organized.

- Cost-Effective: With a lower initial investment compared to full-sized lathes, mini lathes provide an affordable entry point into the world of machining.

- Skill Development: Working with a mini lathe is a great way to develop your machining skills. It permits you to practice techniques like turning, facing, & threading without the intimidation of larger machines.

Uses of Mini Metal Lathe Machine

Mini Metal Lathe Machines are versatile and can be used for various applications. Here are some of the most common uses:

- Metal Turning: This is the primary use for most mini lathes, allowing the user to shape metal rods into cylindrical forms.

- Threading: Mini metal lathes can be used to create threads on screws and bolts.

- Drilling: With the appropriate attachments, mini metal lathes can perform precise drilling tasks, creating clean and accurate holes.

- Facing: This process creates a smooth, flat surface on the end of the metal piece and is commonly used in component finishing.

For more info about the granite engraving machine visit our website.

Tips for Using a Mini Metal Lathe

- Start with Basic Projects: If you’re new to utilizing a lathe, begin accompanied by simple assignments to familiarize yourself with the machine’s capabilities & controls.

- Use Quality Tools: Invest in good-quality cutting tools & accessories to assure optimal performance & longevity.

- Regular Maintenance: Keep your lathe clean and lubricated to maintain its efficiency and prevent wear. Regularly check for any loose parts or debris.

- Safety First: Always wear appropriate safety gear, including goggles and gloves. Ensure your workspace is organized and free of hazards.

- Take Your Time: Precision work mandates patience. Avoid rushing through projects to acquire the best results.

Mini Metal Lathe Machine Price

We are the best mini metal lathe machine manufacturer in India and a global supplier of mini metal lathe machines. Our mini metal lathe machines are offered at competitive prices compared to others in the market. The price of the mini metal lathe machine in India varies depending on the type and specifications of the model. In addition to mini metal lathes, we provide a wide range of other lathe machines, including engine lathes, T-lathes, belt-drive lathes, motor-driven lathes, wood-turning lathes, speed lathes, CNC turning lathes, geared-head lathe machines, and also offer sand blasting machine, abrasive blasting machine, airless shot blasting machine, wheel blasting machine, sand blasting nozzle, sand blasting helmet, pinch valve, deadman handle, sand blasting stencils, abrasive media, etc.