How Lathe Machine Work?

Every manufacturing company needs a lathe machine. If you don’t have one yet, now’s a great time to learn about this handy piece of equipment! Once you comprehend how lathe machine work, you’ll probably wonder why you didn’t obtain one sooner.

A lathe machine is a universal machine equipment mainly utilized for shaping cylindrical entities by extracting material from a jobpiece. It works on the principle of rotating the jobpiece almost its axis whereas a cutting tool is involved in it. The major usefulness is to release undesirable segments of the material, exiting after an agreeably shaped job piece.

There are numerous assortments of lathes certain are specialized for assorted materials & techniques. Here at All Metals Fabricating, we encompass dissimilar varieties of lathes, including a lathe accompanied by live tooling capacities for multitasking work. We also provide engine lathe machines, metal lathe machine, mini lathe machines, and glass lathe machines, etc.

Before getting into how lathe machine work, let’s first comprehend what it is & why it’s useful. A lathe machine is especially utilized to shape cylindrical components assembled of wood & metal. It works by turning the job piece whereas a cutting tool stays still, extracting material to reshape it. Accompanied by a lathe, you could easily make objects like bowls, pens, or furniture parts. It’s distinct from a milling machine. In a milling machine, the cutting tool rotates almost like a standing jobpiece, assembling it sufficiently for shaping oddly shaped materials.

Working Principle of Lathe Machine

A lathe is a straightforward machine, whereas it includes numerous moving elements certain work together. Most lathes incorporate a headstock, tailstock, spindle, motor, chuck, & distinct cutting tools. Here's how it works:

First, the job piece (the material to be shaped) is assured in the chuck. The chuck is the portion certain holds the job piece firmly, usually gripping its outside. The chuck is affixed to the spindle, whichever is powered by a motor. When the motor runs, the spindle spins the job piece.

Once the job piece is spinning, it’s prepared to be cut. The mechanic connects a cutting tool to a tool holder, whichever maintains the tool constant & permits it to drive along the spinning job piece. Cutting tools arrive in distinct sizes & are scheduled for distinct tasks. Turning tools could cut material off of job piece. These flat blades are the numerous typical kinds of cutting tools utilized in lathe work. Further cutting tools contain bland bars to assemble holes larger, chamfering tools to assemble angles, & parting tools to cut the job piece in half.

For more info about the sand blasting machine visit our website.

The lathe machine works on the principle of rotational symmetry:

- The job piece rotates whereas the standing cutting tool extracts material to acquire the preferred shape.

- This process relies on accurate control of speed, feed rate, & cutting deepness to assemble exact & smooth surfaces.

Key Components of a Lathe Machine

- Headstock: Houses the prior spindle & gears. It delivers the rotational motion to the job piece.

- Tailstock: Supports the opposing end of the job piece for stability.

- Carriage: Forces the cutting tool in both longitudinal (along the axis) & transverse (perpendicular to the axis) directions.

- Chuck: Holds & secures the job piece. It could be a 3-jaw (self-centering) and 4-jaw (independent) chuck.

- Tool Post: Incorporates the cutting tool & authorizes its adjustment.

- Bed: The underneath of the lathe, delivering rigidity & endorsement for all elements.

- Feed Mechanism: Incorporates the directive of the & tool automatically.

For more info about the granite engraving machine visit our website.

Basic Working Steps of Lathe Machine

- Mounting the Workpiece: Job piece is securely clamped in the chuck, providing it is centered along the lathe axis.

- Selecting Speed: The operator alters the spindle speed established on the material & desired finish.

- Setting the Cutting Tool: A cutting tool is ascended on the tool post & positioned most comparable to the job-piece.

- Rotation: The spindle rotates the job piece at the specified speed.

- Cutting Process:

- Manual Feed: The operator manually drives the tool to extract material.

- Automatic Feed: The spread mechanism thrusts the tool at a constant rate.

- Shaping the Workpiece:

- Turning: Decreasing diameter along the length.

- Facing: Assembling a flat exterior on the end of the job piece.

- Drilling: Creating holes utilizing a drill proportion affixed to the tailstock.

- Threading: Cutting threads utilizing a threading tool.

- Finishing: Once the preferred shape & dimensions are acquired, the job-piece is released for inspection & further processes if necessary.

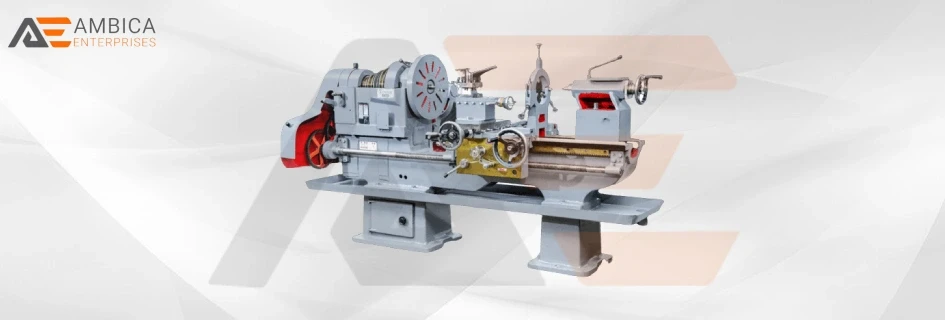

Lathe Machine Manufacturers in India

We are the one lathe machine manufacturers in India and also suppliers of lathe machines all over the world. We offer all types of lathe machines such as engine lathe machines, center lathe machines, speed lathe machines, turret lathe machines, tool room lathe machines, mini lathe machine, and also provide abrasive blasting machines, grit blasting machines, portable sand blasting machines, pressure blasting cabinet, shot blasting machine, sand blasting machine spare parts, thermal spray guns, granite engraving machines, and abrasive media, etc.