What are the Main Parts of Lathe Machine?

A lathe machine is an equipment in the field of machining & manufacturing. It is utilized for shaping, cutting, & drilling assorted materials, including metal, wood, or plastic. To understand how a lathe machine works, it is indispensable to understand its major elements & their functions. This guide delivers a detailed summary of the assorted parts of a lathe machine & their roles in machining procedures.

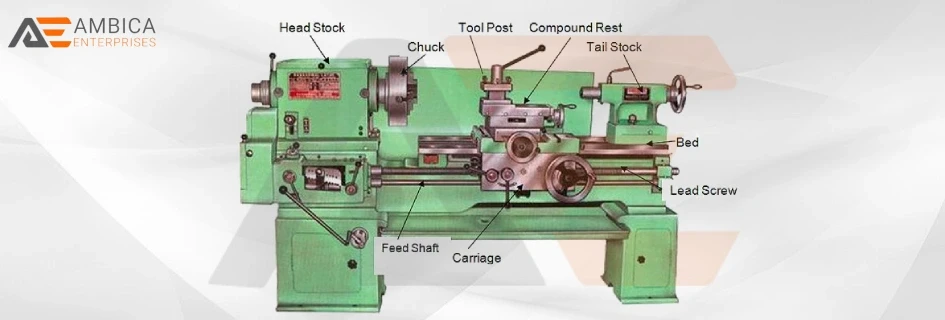

Parts of a Lathe Machine

Lathe machines incorporate several elementary parts certain work concurrently to acquire distinctive machining assignments. Beneath is a breakdown of the primary elements:

Headstock

The headstock, encountered on the left side of the lathe machine, boards the spindle, gears, & motor, whichever rotates the job piece.

Features of Headstock

- Spindle: A rotating shaft certain holds & spins the job piece.

- Gearbox: Permits for speed adjustment of the spindle.

- Chuck: A clamping equipment certainly ensures the job piece.

Tailstock

The tailstock is situated opposite the headstock. It delivers support for long job pieces & holds tools such as drills & reamers.

Functions of Tailstock

- Acts as consent for the additional end of the job piece.

- Contains tools for procedures like drilling & reaming.

- Could be altered along the lathe bed to accommodate dissimilar job piece lengths.

Lathe Bed

The lathe bed is the underneath of the machine & supplies stability. It is assembled of cast iron to withstand vibrations & strengthen precision.

Features of Lathe Bed

- Keeps the headstock, tailstock, & carriage.

- Has hardened guideways to secure the smooth motion of elements.

For more info about the wheel blasting machine visit our website.

Carriage

The carriage is a comforting element certain supports the cutting tool & regulates its movement. It consists of several subcomponents:

Subcomponents of Carriage

- Saddle: The part certain slides on the bed.

- Cross-Slide: Permits for transverse motion of the cutting tool.

- Compound Rest: Enables angular movement of the tool.

- Tool Post: Contains the cutting tool securely.

- Apron: Contains controls for the spread mechanism.

Chuck

The chuck is connected to the spindle & is utilized to grip & maintain the job piece. It arrives in distinct kinds hanging on the machining necessities.

Types of Chuck

- 3-Jaw Chuck: Self-centering & generally utilized for round job pieces.

- 4-Jaw Chuck: Independently modifiable jaws for irregularly shaped job pieces.

- Collet Chuck: Supplies precision gripping for small & delicate parts.

Lead Screw

The lead screw is a long threaded shaft certain runs comparable to the bed. It is utilized for threading procedures & controls the motion of the carriage during machining.

Functions of Lead Screw

- Facilitates threading by synchronizing the tool motion with spindle rotation.

- Delivers accurate longitudinal action of the carriage.

Feed Rod

The feed rod is another shaft that operates parallel to the bed & controls the mechanical movement of the carriage during turning procedures.

Difference Between Feed Rod & Lead Screw:

- The feed rod is employed for wide turning procedures.

- The lead screw is especially utilized for threading.

For more info about the engine lathe machine visit our website.

Spindle

The spindle is a rotating shaft encountered in the headstock. It includes the chuck & job piece, assuring smooth & precise rotation.

Key Features of Spindle

- Furnishes rotational movement to the job piece.

- Authorizes for adjustable speeds via the gearbox.

Gearbox

The gearbox is part of the headstock & authorizes the operator to modify the spindle speed to correspond the necessities of the machining procedure.

Tool Post

The tool post is ascended on the carriage & contains the cutting tool securely in position.

Types of Tool Posts

- Single-Tool Post: Contains one cutting tool.

- Four-Way Tool Post: Holds numerous tools for fast changes.

- Quick-Change Tool Post: Enables fast tool differences for improved efficiency.

Apron

The apron is affixed to the front of the carriage & incorporates controls for the spread mechanism & threading processes.

Key Controls

- Levers for employing the feed rod & lead screw.

- Controls for automatic tool movement.

Bed Guideways

The guideways are hardened & precision-ground exteriors on the lathe bed certainly guide the movement of the carriage & tailstock.

Compound Slide

The combination slide is mounted on the cross-slide and authorizes angular adjustments of the cutting tool.

Steady Rest & Follower Rest

These accessories deliver further support for long & slender job pieces to contain bending or deflection.

Steady Rest:

Sustains the job piece at a fixed point.

Follower Rest:

Thrusts with the carriage to deliver constant support.

Thread Dial Indicator

This device is utilized during threading procedures to provide appropriate alignment of the cutting tool with the job piece threads.

Lathe Machine in India

We are the leading manufacturer and supplier of lathe machine in India at low price with the best quality. We also offer all types of lathe machines including engine lathe machines, glass lathe machines, center lathe machines, gear head lathe machines, bench top lathe machines, and also provide all types of abrasive blasting machines, grit blasting machines, sand blasting machine, sand blasting cabinets, sand blasting nozzles, sand blasting hose, internal pipe blasting equipment, sand blasting safety equipment, thermal spray gun, arc spray gun, thermal spray wire, and abrasive media, etc.